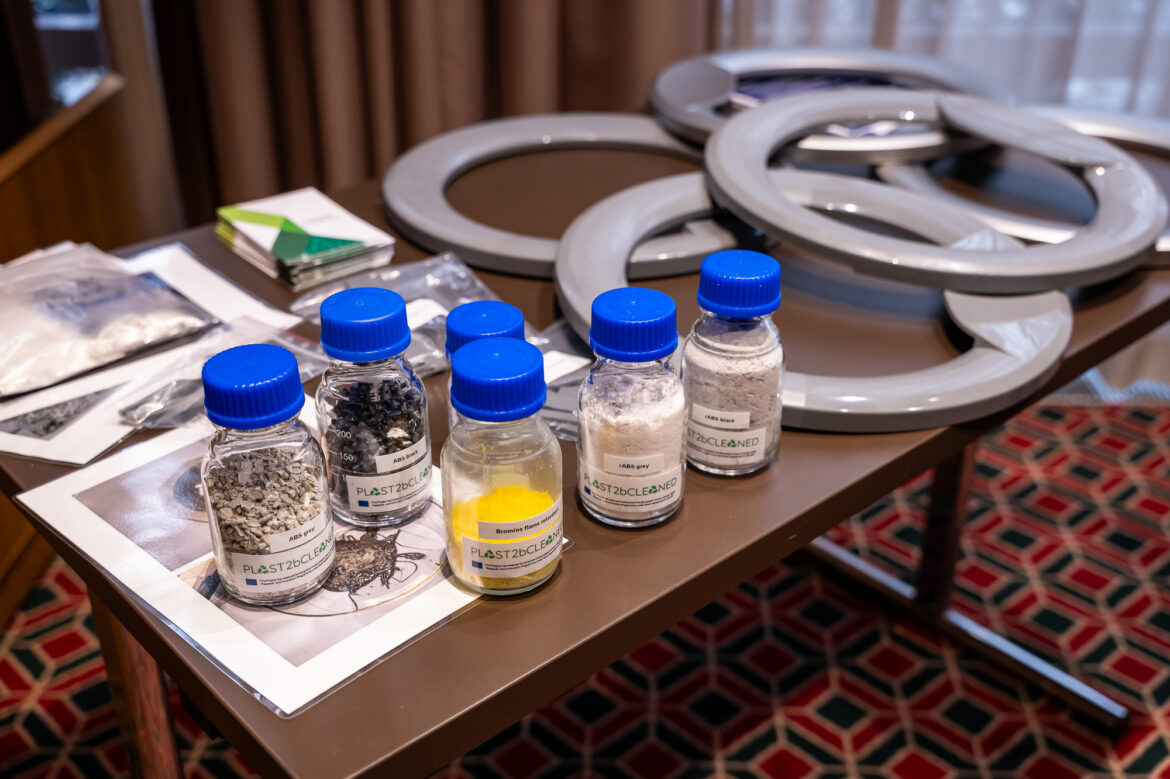

Among the notable accomplishments of the PLAST2bCLEANED project is the successfully production of ABS from WEEE using an energy-saving process, indicating an economical viable avenue. Additionally, the team at Electrolux was able to create 23 door frames from this material after it was recompounded at ELIX Polymers, incorporating an impressive 30% of this eco-friendly recycled ABS. Remarkably, this was achieved without any alterations to the original process, demonstrating the project’s ability to integrate sustainable materials without compromising quality.

The plant that was built in a technology readiness level 5 of the project (that means demonstration pilot) at the site of Fraunhofer ICT in Pfinztal, Germany, was approved in February 2023 and will provide a kilogram scale of recycled Acrylonitrile butadiene styrene (ABS) in addition to recovered bromine and antimony fractions, all components of waste electric and electronic equipment.

This purified ABS will then be further processed and tested by other partners (ELIX Polymers and Electrolux) shortly.

This brings PLAST2bCLEANED closer to demonstrating that environmentally safe and economically viable recycling of antimony, bromine and polymers is possible.

PLAST2Bcleaned’s testing and scale-up efforts at Fraunhofer ICT in Pfinztal, Germany, are progressing well.

After the solvent-based purification method has through laboratory testing and trials, a pilot plant is built to enable scaling up and advancement of PLAST2bCLEANED.

In the pilot, three loops (ABS, bromine, and antimony), will be closed while testing Acrylonitrile Butadiene Styrene (ABS) polymers incorporating brominated flame retardants and antimony trioxide.

Fraunhofer ICT team members, who are in charge of the project’s process system integration and scale-up, visited JUCHHEIM Laborgeräte GmbH, the German company in charge of the pilot unit dissolution tasks, in Bernkastel-Kues to see the ongoing procedure.

The separation vessels were being produced, and the dissolving vessel was almost ready.

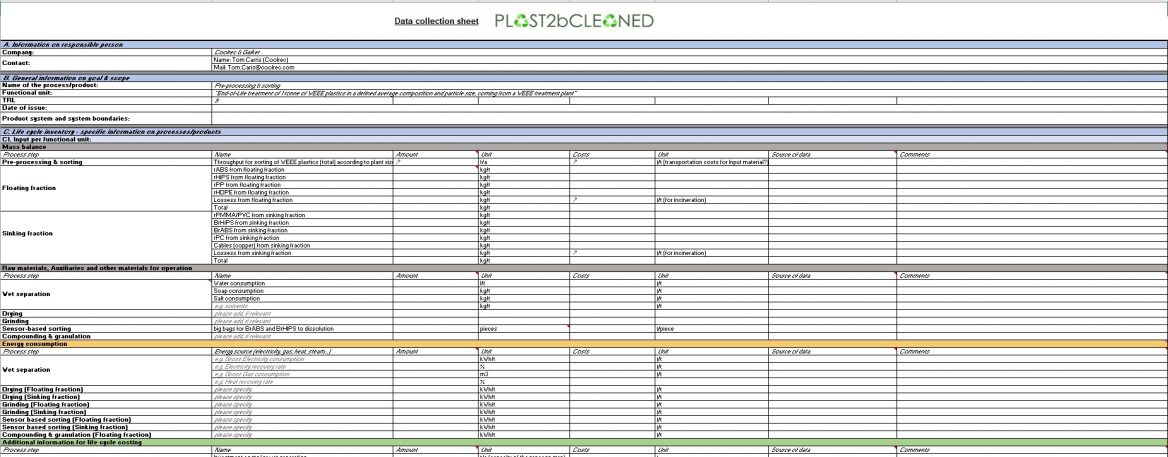

Screenshot of PLAST2bCLEANED’s Inventory data collection sheet for the full LCA/LCC

As part of the tasks PLAST2bCLEANED is developing, the project is carrying out both a life cycle assessment (LCA) and a life cycle costing (LCC). During this first period, the main objective has been to establish the final methodological approach, as well as to develop a detailed and complete inventory data collection sheet.

To achieve this, first, the consortium decided on the final goal and scope, and PLAST2bCLEANED system’s definition and graphical description were updated to the latest insights from the PLAST2bCLEANED current research and prepared for the final assessment.

Likewise, a small-scale study was conducted on technology upscaling and learning methods, enabling the translation of lab-scale data to real data from a simulated commissioned and operative plant in Europe (sensitivity for countries, electricity mix, etc.) The aim of this research was to test the sorting and dissolution technologies under development on the project, to prove them valid and replicable, and it was finally validated by experts from the consortium and improved in the data collection sheet.

Results were shared with similar initiatives addressing plastics recycling like NONTOX and CREAToR to align the methodology framework and establish a common ground for future projects.

Finally, a detailed inventory data collection sheet was prepared and sent out within the project with an updated process flow diagram for partners’ input.

In the following months, TNO, responsible for these tasks for PLAST2bCLEANED, will collect all the inventory data and perform an LCA and LCC study for the final assessment.

PLAST2bCLEANED produced samples at lab scale to verify if the final produced products are fulfilling the specifications needed within the project. The laboratories in Israel of the bromine recovery expert ICL Group analysed these samples for the different bromine compounds.

Once PLAST2bCLEANED is ready and scaled up, the produced bromine used in brominated flames retardants coming out of the Dead Sea will get a second life in Europe after their recovery at ICL Group premises in Terneuzen (Netherlands).

In the PLAST2bCLEANED project, Raman spectroscopy is researched to improve the sorting of the polymers High Impact Polystyrene (HIPS) and Acrylonitrile Butadiene Styrene (ABS) within the recycling process of Waste of Electric and Electronic Equipment (WEEE).

WEEE plastics usually contain certain additives like pigments or brominated flame retardants (BFR), which sometimes make difficult the correct identification of polymers with spectroscopic techniques. Certainly, the Raman spectrum of some WEEE samples presents a fluorescence or scattering effect that masks the Raman signal of the polymer. To overcome this technical challenge, in the PLAST2bCLEANED project Chemometrics is studied in combination with Raman spectroscopy for WEEE polymers identification.

Chemometrics is a tool that uses mathematical and statistical methods to analyse and extract relevant information from a data matrix. It is based on Multivariate Analysis (MVA), which assesses the information within many variables in the measured data to find the relationship between samples and variations in a data set.

Applied to Raman spectroscopy, MVA is used to find main patterns and correlations in spectral data in order to establish a measurable relationship between the registered spectra and the variable or characteristic object of the study. Principal Component Analysis (PCA) together with several pre-treatment algorithms are initially applied to spectral data with the objective of separating valuable information contained in the data structure from the signal due to other sources and spectral noise.

Once the spectra have been pre-processed, multivariate models are built and tested to classify analysed samples into target categories by using pattern recognition. All these techniques are being evaluated within the PLAST2bCLEANED project to analyse Raman spectral data and to define a classification model for sorting HIPS and ABS from WEEE streams.

In PLAST2bCLEANED, Raman spectroscopy is applied for the pre-processing step of the recycling process, in order to improve the current sorting process of Waste Electric and Electronic Equipment (WEEE) plastics.

Raman spectroscopy is an analytical technique based on light scattering that uses a laser as a source of high intense monochromatic light. Different laser wavelengths ranging from ultraviolet (UV) to near-infrared (NIR) can be employed. The sample is irradiated with the laser beam and scattered radiation of different wavelengths is produced. The scattered light is detected in the spectrometer, which transforms the signal into a spectrum.

The Raman spectrum is a chemical fingerprint of a compound that gives information about its molecular structure. Consequently, Raman spectroscopy is a useful technique for chemical identification, being complementary to other spectroscopic techniques used for plastics sorting in recycling plants, such as NIR spectroscopy.

In order to maximise the Raman signal and to reduce the fluorescence effect, several parameters are evaluated for polymers identification: laser power, integration time, or the use of different laser wavelengths in the NIR range.

PLAST2bCLEANED aims to develop a mechanical sorting process based on Raman spectroscopy, that will lead to identifying several polymers in any colour which contain different additives like brominated flame retardants (BFR) or pigments, in order to separate High Impact Polystyrene (HIPS) and Acrylonitrile Butadiene Styrene (ABS) fractions from WEEE streams. These sorted polymers will be further purified for their reuse in other applications.